Converting 4-Slide Into Standard Vertical Stamping

"Convert our old, 4-slide tooling into standard vertical punch press tooling and deliver parts to us in just two weeks."

At Acro, we welcome challenges. Solving tough problems is what we do best.

We had a buyer approach us as a new customer in dire need of parts to keep their supply chain intact. Their previous metal stamper had unexpectedly closed its doors, creating a production emergency.

Even before the purchase order was finalized, we took the initiative to quote the raw material needed through one of our trusted material suppliers and had them stage the material for shipment so we could hit the ground running once we received a PO.

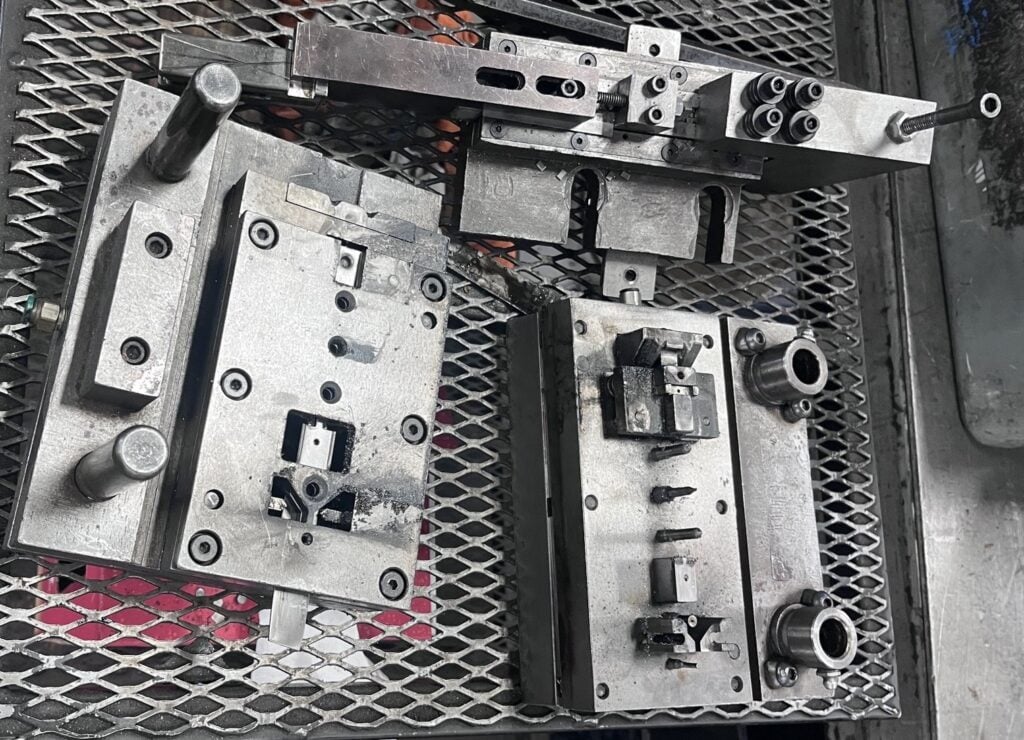

When retrofitting the die, we ran into a key challenge: the original tooling was designed for a 4-slide press, forming parts from multiple directions. We needed to replicate that same motion within our vertical servo presses.

Our team developed a solution using a pneumatic cylinder actuated by a cam to replicate the original 4-slide motion. We mounted the 4-slide die components into a repurposed die shoe, making it possible to install and run them efficiently in our vertical presses. Using our servo presses, we programmed a pause in the stroke to allow the cylinder to actuate from a different angle.

Thanks to our fully programable A/C motor presses, we not only hit the deadline but also created a consistent, repeatable setup that will make future production quicker and easier.

See the video below to see this die running.