Custom Stamping & Engineering

ACRO Metal Stamping provides USA-based custom stamping and engineering utilizing the latest technology. We are a prime producer of precision stampings in all shapes, sizes, and materials, specializing in running progressive and compound dies produced in our in-house toolroom.

The Trusted Choice for

Precision Metal Stamping

MANUFACTURED IN THE USA

TIGHTER TOLERANCES

IN-HOUSE

TOOL ROOM

DIE DESIGN &

RE-ENGINEERING

Higher quality and larger cost savings are within reach

Experts in tight tolerance and complex metal component manufacturing

For over 75 years, ACRO Metal Stamping has been a low cost stamping and assemblies supplier. We build and maintain all of our own dies in-house, reducing cost, improving quality, and generating faster turnaround times. Plus our engineers can help adjust your design for the lowest cost production, while providing higher quality, and better manufacturability. ACRO also has more Servo Presses than any other job shop in the Midwest, making ACRO Metal Stamping the trusted choice for all your stamping needs.

Are you looking for higher quality & better manufacturability?

Services & Capabilities

We specialize in the production of tight tolerance components including: Extrusion Inserts & Gaskets, Electrical Connectors & Terminals, Shims, Bearings, Washers, Drawn Cups, and Discs.

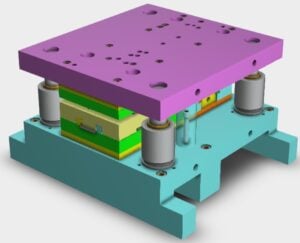

Acro Metal Stamping specializes in progressive and compound dies produced in our in-house toolroom. We design, build and maintain all of our own dies in-house, which helps reduce cost, improve quality, and generate faster turnaround times. Acro stores, repairs and maintains all customer dies at no cost to customer while tooling. We also provide fast tool modifications to accommodate engineering changes.

Our engineers can help adjust your design for the lowest cost production, while providing you with higher quality, and better manufacturability.

Acro Metal Stamping is equipped with the necessary tools to inspect complete first piece, in process, and final product. To provide confidence in our production processes, Statistical Process Control (SPC) is utilized on all critical dimensions and Production Part Approval Process (PPAP) as needed.

- Deburring/finishing

- Assembly

- Riveting

- Welding

- Tapping – up to 1″diameter and 5″ thickness

- CNC machining

- Drilling

- Special Packaging

- Hydraulic Inserting

Acro Metal Stamping has invested in new high speed production equipment to provide our customers with the most cost efficient method of producing large quantities of metal components. Investing in automation and hybrid AC Servo presses allows us to drive labor and maintenance costs down. Acro Metal Stamping has more Servo Presses than any other job shop in the Midwest, making us the trusted choice for our customers stamping needs.

- 2-220 TON KOMATSU SERVO PRESS H1F200

- 1-150 TON FEDERAL STRAIGHT SIDE

- 1-150 TON BLISS

- 1-150 TON NIAGARA AA61/2

- 1-135 TON NIAGARA AA5 1/2

- 1-110 TON KAMATSU SERVO PRESS H1F110

- 1-125 TON JOHNSON

- 1-90 TON NIAGARA A5

- 1-87 TON VERSION 7-S

- 1-80 TON KAMATSU SERVO PRESS H1F80

- 1-70 TON FEDERAL

- 1-60 TON KAMATSU SERVO PRESS H1F60

- 1-60 TON BLISS #6

- 2-60 TON FEDERAL VERTICAL

- 3-60 TON FEDERAL

- 1-45 TON KAMATSU SERVO PRESS H1F45

- 2-45 TON FEDERAL PRESSES

- 1-45 TON BLISS

- 3-35 TON KAMATSU

- 3-35 TON BLISS PRESSES

- 2-32 TON HORIZONTAL FEDERAL

Need a specialist in progressive or compound dies?

Testimonials

Christie Tyler

Christie TylerBuyer/Planner

Gregg Hackney

NORAM

North American Clutch Corporation

Charles Geurts

Charles GeurtsSupply Quality Engineer

Steve Brinker

Steve BrinkerPurchasing and Logistics Manager

Chris Miller

Chris MillerSenior Buyer

Kirk Tyler

Kirk TylerMaster Scheduler