Seamless Tooling Transfer in 3 Simple Steps

Step 1: Free Tooling Review

We assess your die specs, part print, or samples to confirm transfer fit and identify any retrofitting costs.

Step 2: Initial Run

We fit the tooling to our presses, run tests, inspect parts, and confirm performance with your quality team.

Step 3: Part Approval & Full Production

We deliver PPAP documentation as needed and start full-scale production.

Ready for a Hassle-Free Transfer? Get Started Today.

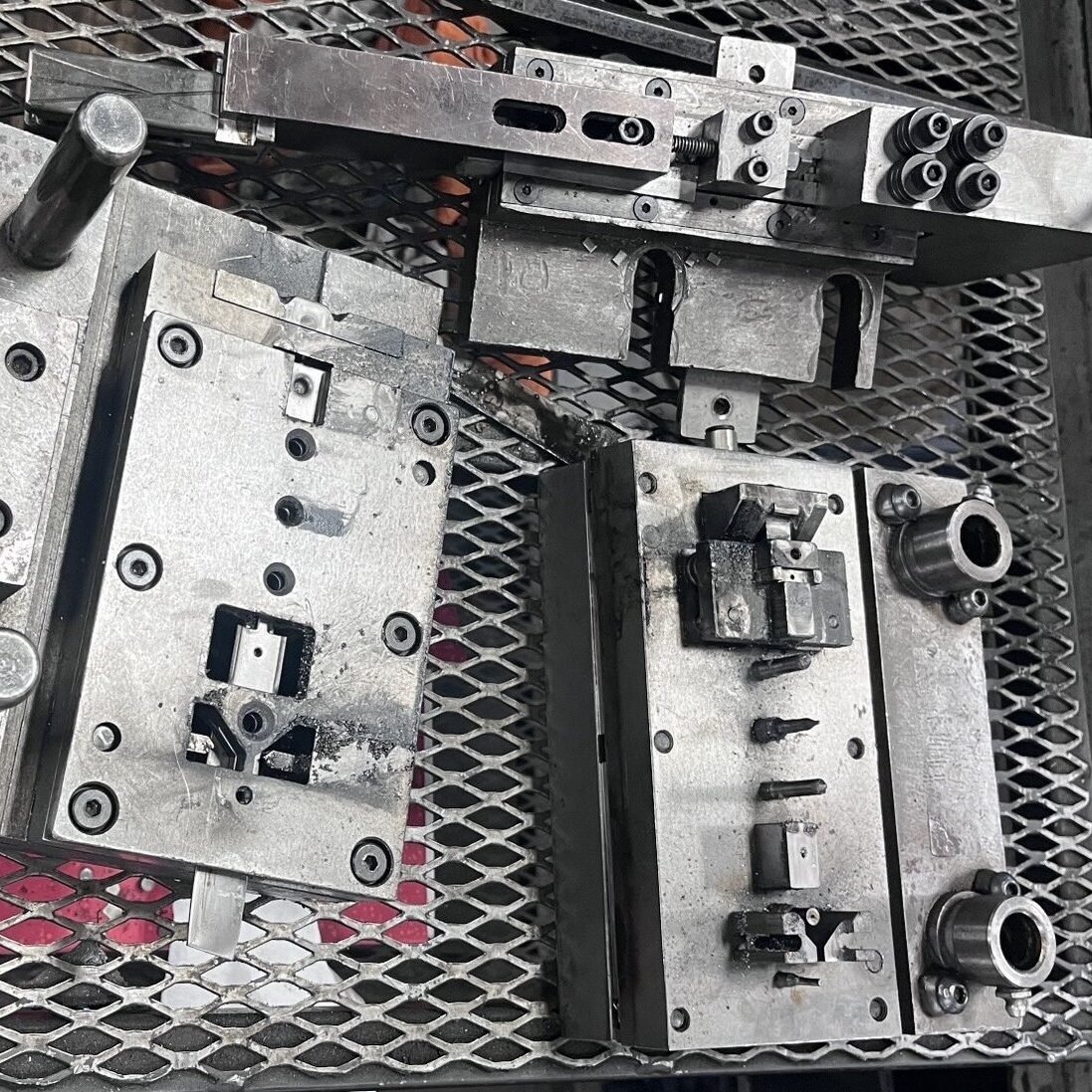

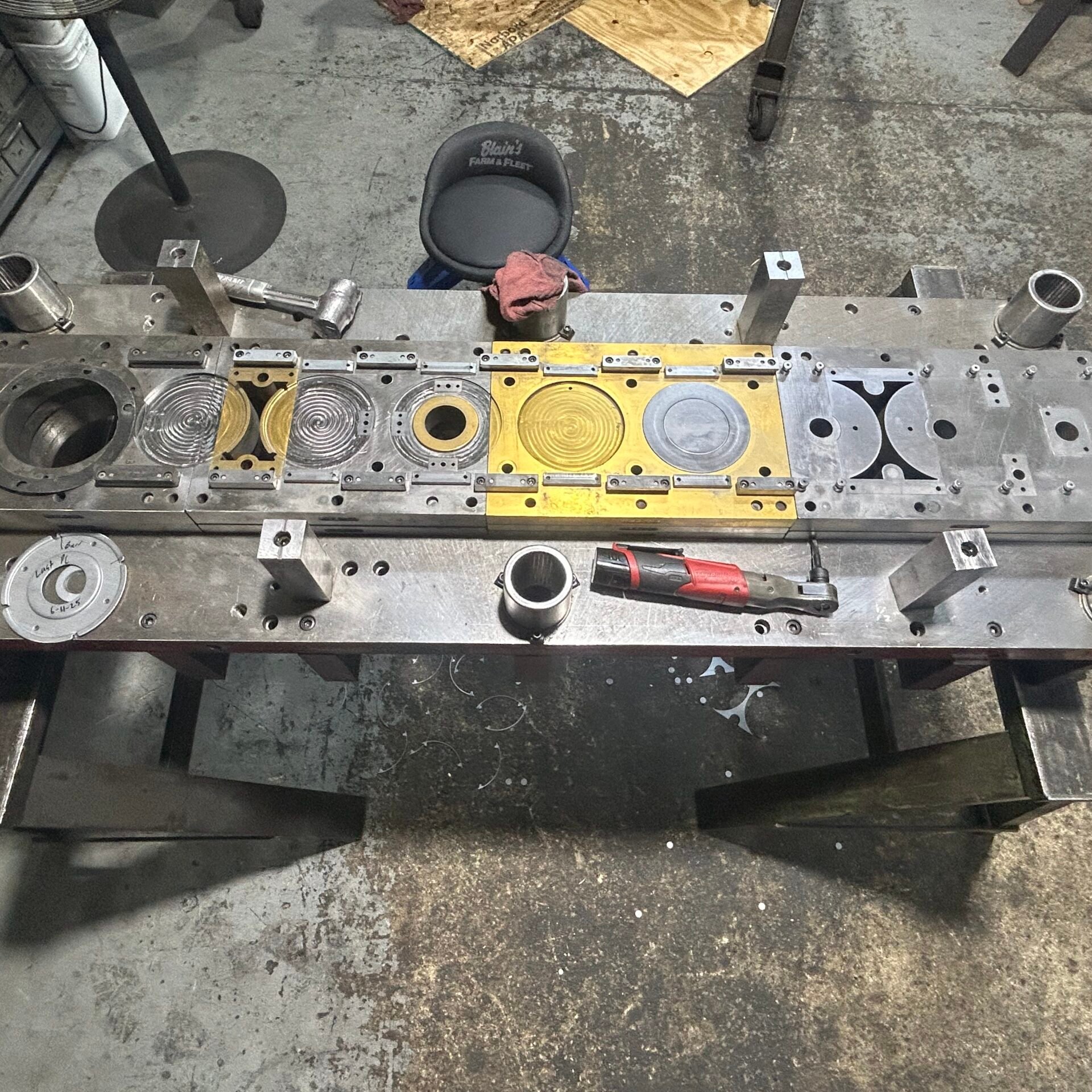

Discover the Value of Our In-Facility Toolroom

Fully Equipped. Expertly Staffed.

Our in-house toolroom is powered by skilled die makers, designers, and engineers who handle every stage of tooling transfers, repair, and maintenance to ensure your dies run at peak performance.

✅ Custom Tooling: We redesign, rebuild, and maintain transferred progressive and compound blank dies to meet your exact requirements.

✅ Fast Turnarounds: Dedicated equipment enables quick modifications and new tool development.

✅ Maximized Uptime: Preventative maintenance and timely repairs reduce downtime and extend tool life.

How Moving 80+ Tools to Acro Solved this Customer's Supply Chain Emergency