Acro News & Information

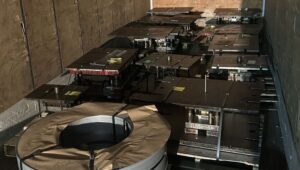

More Dies Sent To Acro

When a Customer Sends “The Rest” of the Dies: What That Really Means In metal stamping, trust isn’t built with promises. It’s built with parts. Recently, we had a customer send us the last of their remaining dies after we successfully took over production on their initial tool transfer. That moment says more than any sales pitch ever could – and it highlights what really matters when transferring customer-owned tooling. This wasn’t just a…

Pre-Tempered vs. Post-Heat-Treated Metal Stamping

Design & Manufacturing Expertise from Acro Metal Stamping Choosing whether to stamp parts from pre-tempered material or to heat treat after stamping is one of the most important decisions in precision metal stamping. The choice affects part performance, tooling cost, dimensional stability, lead time, and long-term quality. At Acro Metal Stamping, we help engineers and purchasing teams make the right decision early-avoiding unnecessary secondary operations, tooling issues, and redesigns. With decades of experience stamping spring…

Specialize In Customer Owed Tooling

Acro Metal Stamping: The Ideal Partner for Transferring Your Customer-Owned Tooling In the world of precision metal stamping, tooling ownership and performance are two of the most critical factors that determine production success. For manufacturers who rely on external stampers, the need to transfer dies-whether due to capacity constraints, quality challenges, or a stamper closing their doors-is a reality that demands a reliable partner. That’s exactly where Acro Metal Stamping shines. With over 80 years…

Do I Own My Tool?

Tooling Ownership in Metal Stamping: What Customers Should Know-and How We Handle It In metal stamping, tooling is everything. Progressive dies and form tools represent a major investment; and play a critical role in part quality, consistency, and long-term supply stability. Yet one of the most common-and most misunderstood-questions customers have is: “Do we own the tooling?” At Acro Metal Stamping, we believe tooling ownership should never be ambiguous. Clear expectations protect both the customer…

Updated Metal Part Costs Guide

Download PDF Below are the primary factors that influence the total cost of a metal component-from concept through production. Understanding these drivers helps identify opportunities for cost reduction without sacrificing performance or reliability. 1 Production Method – Often the Largest Cost Driver Production method is typically dictated by volume, but tolerances, material type, geometry, design complexity, and functional requirements also influence the choice. Approximate order of decreasing cost (highest → lowest): Machining Metal Fabrication (laser,…

Spring Washer Manufacturing

Understanding Metal Stamping Spring Washers: Design, Function, and Manufacturing Advantages Spring washers-sometimes called disc springs, Belleville washers, or simply spring lock washers-are essential components in mechanical assemblies that require controlled tension, vibration resistance, or load distribution. While they may appear small and simple compared to the larger parts they support, their performance is often critical to the reliability and safety of the entire system. One of the most efficient and scalable ways to produce spring…

Why Change Stampers

Why an OEM Might Move Their Stamping Dies from One Stamper to Another In the world of precision metal stamping, relationships between OEMs (original equipment manufacturers) and their contract stampers often span years or even decades. Yet despite the long-standing nature of these partnerships, situations arise where an OEM decides to relocate its tooling-sometimes dozens of dies-from one stamper to another. This decision is never taken lightly. It carries implications for production continuity, quality, cost,…

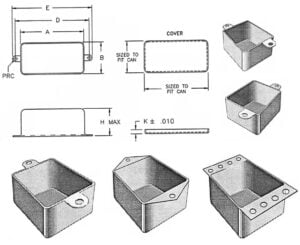

RFI Enclosure Stamping Process

In today’s electronics-driven world, electromagnetic interference (EMI) and radio frequency interference (RFI) are major design concerns across industries-from automotive control modules to medical instruments and telecommunications. Metal enclosures play a critical role in shielding sensitive circuits from unwanted electromagnetic noise. Among the various manufacturing methods available, metal stamping has emerged as one of the most efficient, precise, and scalable processes for producing RFI enclosures. This article explores the stamping process, material selection, design considerations, and…

Electrical Terminal Stamping Process

Copper electrical terminals are fundamental components in electrical and electronic systems, providing the interface between conductors and devices. High-volume production of these terminals requires precision, repeatability, and cost efficiency, all of which are achieved through progressive die stamping. This article details the materials, tooling design, process flow, quality control, and post-processing steps involved in the stamping of copper terminals, with emphasis on the factors that influence electrical and mechanical performance. 1. Introduction Electrical terminals must…

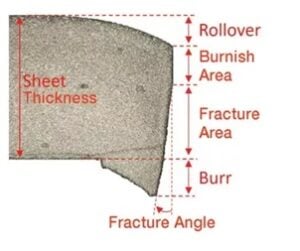

Explaining The Break Edge

During the stamping process metal is not so much cut as it is broken out. This means that a clean edge only exists for a portion of that edge; and a rougher broken edge shows for the rest. With traditional punch presses, a good standard was about 1/3 of the material thickness would be cut sheer and the other 2/3 would be broken. The “sheer” or “land” portion of the cut can be improved upon…

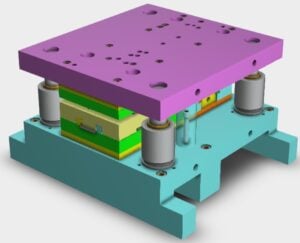

Debugging Dies Virtually

We at Acro were so fortunate to add a new designer to our Famiy this year; who brought a fresh understanding of the latest technology. We’ve now been able to utilize some of the capabilties build into the specifically for metal stamping plug in for solidwards called Lgogpress that we use. Most beneficially recently; we’ve been able to utilize the “Die Debugger”; which allows us to virtually run the die in one of our presses. …

No Boxes, No Hassle—Just Dependable Deliveries

Smarter Packaging. Dependable Deliveries. ✅ Reusable Totes ✅ Custom-fit Packaging ✅ Custom Labeling ✅ Monthly Shipments ✅ In-House Services ✅ Flexible Sourcing ✅ Built for Growth ✅ Reliable & On Time ✅ Zero Carboard Waste ✅ Cost Effective ✅ Sustainability ✅ Reduced Packaging Waste Monthly Delivery-Ready to Go Out the Door! Best thing is… not a single cardboard box used! We worked with our customer to develop a reusable tote solution that fits the 10+…

MANUFACTURED IN THE USA

TIGHTER TOLERANCES

IN-HOUSE TOOL ROOM