Do I Own My Tool?

Tooling Ownership in Metal Stamping: What Customers Should Know—and How We Handle It

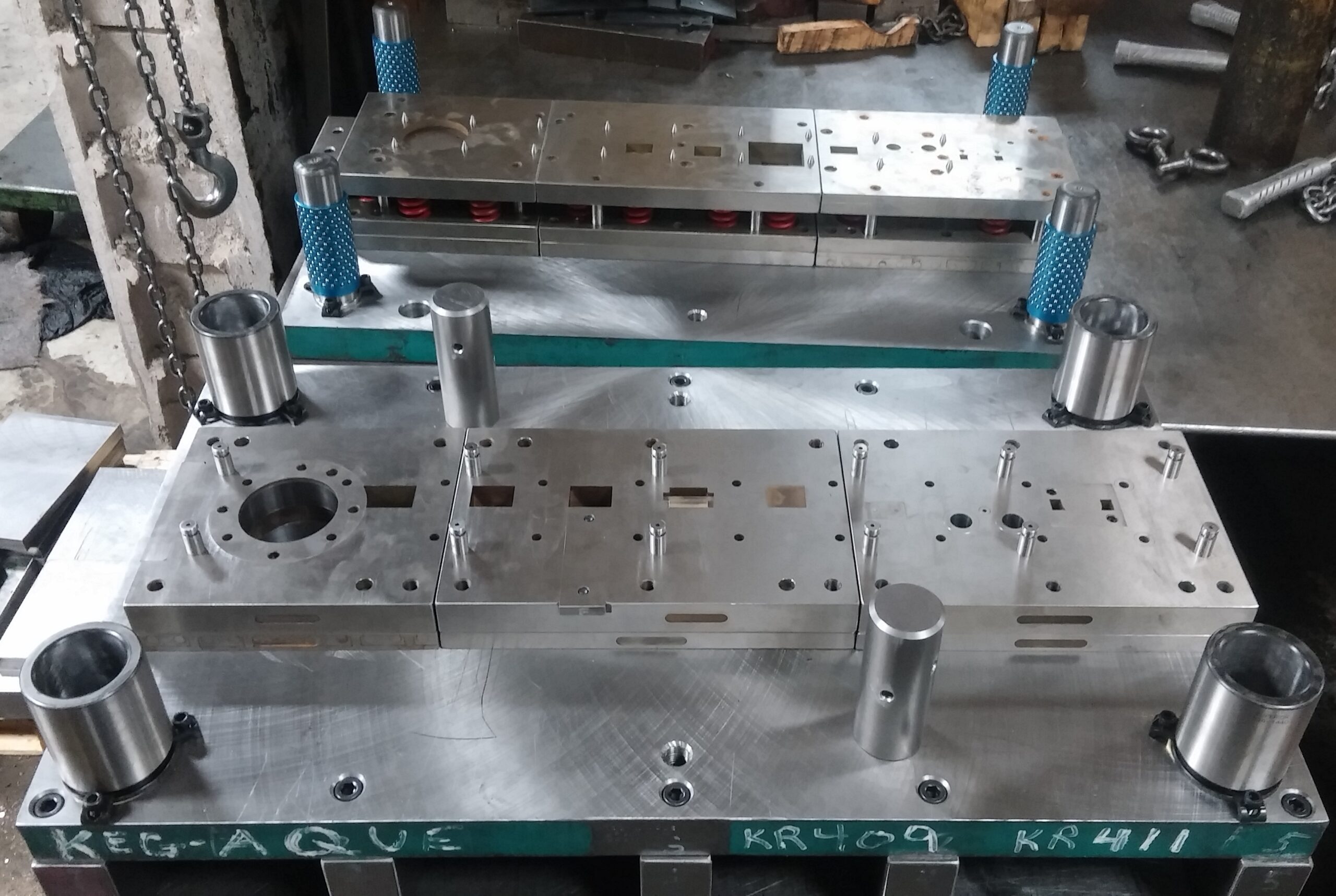

In metal stamping, tooling is everything. Progressive dies and form tools represent a major investment; and play a critical role in part quality, consistency, and long-term supply stability. Yet one of the most common—and most misunderstood—questions customers have is:

“Do we own the tooling?”

At Acro Metal Stamping, we believe tooling ownership should never be ambiguous. Clear expectations protect both the customer and the manufacturer, reduce risk, and create stronger long-term partnerships. Below, we explain how tooling ownership is typically determined in metal stamping—and how we ensure clarity from day one.

Why Tooling Ownership Matters

Tooling ownership impacts far more than accounting. It affects:

-

Your ability to move production if needed

-

Long-term cost control

-

Intellectual property protection

-

Business continuity and risk management

Unclear ownership can lead to disputes, production delays, or unexpected costs when a program changes. That’s why we address tooling ownership explicitly—before the first part is ever stamped.

How Tooling Ownership Is Determined

Tooling ownership in metal stamping is not assumed. It is established through a combination of contractual, financial, and operational factors.

1. Written Agreements Come First

The most important determinant of tooling ownership is the written agreement. This may include:

-

A tooling purchase agreement

-

A master supply agreement

-

A quotation with tooling terms clearly defined

When tooling is customer-owned, our documentation explicitly states that the tooling is the property of the customer. There is no guesswork, no verbal assumptions, and no fine print surprises.

2. How the Tooling Is Paid For

Payment structure plays a major role in ownership:

-

Customer-funded tooling: When tooling is invoiced separately and paid for directly, ownership is straightforward.

-

Amortized tooling: When tooling costs are included in part pricing, ownership is defined in writing once amortization is complete.

-

Supplier-funded tooling: If tooling is not paid for, ownership typically remains with the supplier unless otherwise agreed.

3. Physical Identification and Asset Control

Customer-owned tooling is typically:

-

Clearly labeled or tagged as customer property

-

Tracked with unique tool identification numbers

-

Maintained separately from supplier-owned tools

This helps ensure proper handling, traceability, and accountability throughout the life of the program.

4. Accounting Transparency

When customers own tooling, it is commonly:

-

Capitalized on their books

-

Depreciated over its useful life

We support this process by providing detailed tooling invoices, documentation, and asset references that align with customer accounting requirements.

5. Access, Inspection, and Audit Rights

Ownership includes visibility. Customer-owned tooling should be:

-

Available for inspection upon reasonable request

-

Maintained according to agreed standards

-

Auditable for condition and capability

We welcome tooling audits and inspections because they reinforce trust and demonstrate our commitment to responsible stewardship of customer assets.

6. Maintenance and Responsibility

Tooling agreements typically define who is responsible for:

-

Routine maintenance and sharpening

-

Repairs or rebuilds

-

Damage outside normal wear

Clear responsibility prevents misunderstandings and ensures tooling remains production-ready over the long term.

7. End-of-Program and Transfer Rights

One of the most critical moments for tooling ownership clarity is when a program ends or moves.

When tooling is customer-owned:

-

Customers retain the right to relocate tooling

-

Transfer terms are defined in advance

-

Lead times and logistics are agreed upon upfront

We believe customers should never feel “locked in” by unclear tooling arrangements.

Our Approach: Clarity, Transparency, and Partnership

At Acro Metal Stamping, we treat tooling ownership as a foundational part of program setup—not an afterthought. Our approach includes:

-

Clear tooling ownership language

-

Separate tooling documentation when applicable

-

Open access to tooling status and condition

-

Defined maintenance and end-of-life procedures

Whether tooling is customer-owned or supplier-owned, we make sure expectations are clearly documented and mutually understood.

Why Customers Choose Us

Customers work with us because we:

-

Reduce risk through clear documentation

-

Protect customer investments

-

Support long-term, flexible sourcing strategies

-

Operate with transparency and accountability

Tooling represents trust. We take that responsibility seriously.

Let’s Talk About Your Tooling Strategy

If you’re quoting a new metal stamping program—or reviewing an existing one—we’re happy to discuss tooling ownership options that best support your business goals.

Have questions about tooling ownership, transferability, or cost structure?