Spring Washer Manufacturing

Understanding Metal Stamping Spring Washers: Design, Function, and Manufacturing Advantages

Spring washers—sometimes called disc springs, Belleville washers, or simply spring lock washers—are essential components in mechanical assemblies that require controlled tension, vibration resistance, or load distribution. While they may appear small and simple compared to the larger parts they support, their performance is often critical to the reliability and safety of the entire system. One of the most efficient and scalable ways to produce spring washers is through metal stamping, a manufacturing method used across industries from automotive to aerospace to general industrial hardware.

This article explores what spring washers are, how metal stamping is used to make them, the key design considerations that go into their development, and why stamped spring washers remain a preferred solution for many engineering applications.

What Is a Spring Washer?

A spring washer is a type of washer designed not just to distribute load but also to provide elasticity in a bolted or screwed joint. Unlike a flat washer, which primarily protects surfaces, a spring washer stores mechanical energy and exerts a consistent clamping force.

Common functions include:

-

Maintaining tension in bolted joints as materials expand, contract, or shift

-

Absorbing vibration, reducing loosening due to dynamic loading

-

Taking up axial play in assemblies

-

Compensating for wear or thermal cycling over the product’s life

Spring washers can be made in a variety of forms, including:

-

Split lock washers

-

Belleville (conical) washers

-

Wave washers

-

Crescent or finger washers

The choice depends on load requirements, deflection characteristics, space constraints, and the application environment.

The Role of Metal Stamping in Spring Washer Manufacturing

Metal stamping is the process of feeding sheet metal or strip stock into a die set, where high-tonnage presses cut, form, and shape the material into a finished or near-finished part. For spring washers, metal stamping is particularly advantageous due to its speed, precision, and repeatability.

1. High-Volume Production Efficiency

Spring washers are produced in enormous quantities—millions per year in some industries. Stamping allows for extremely fast cycle times, often producing a washer with each stroke of the press. Progressive dies can pierce, blank, form, coin, and deburr the washer in one continuous motion.

2. Tight Dimensional Control

Critical features such as inside diameter, outside diameter, thickness, and formed height must be held to specification to ensure consistent spring performance. Stamping dies are capable of meeting tight tolerances and maintaining them over long production runs.

3. Material Flexibility

Stamped spring washers can be produced from various alloys, including:

-

Carbon spring steels (e.g., 1074, 1095)

-

Stainless steels (301, 302, 17-7 PH)

-

Copper alloys for electrical applications

-

Specialty nickel or high-temp alloys for aerospace and energy systems

The ability to stamp from coil stock makes it simple to switch materials or gauges for different product lines.

4. Consistent Spring Properties

Spring washers must flex predictably. Metal stamping—combined with heat treating—ensures consistent hardness, tensile strength, and spring characteristics.

5. Cost Advantages

Compared to machining, wire forming, or other metalworking methods, stamping often offers the lowest cost per piece, especially for medium-to-large production quantities.

Key Design Considerations for Stamped Spring Washers

Designing an effective spring washer involves both mechanical and manufacturing considerations. Engineers must balance performance, manufacturability, and cost.

1. Material Selection

The alloy determines fatigue performance, temperature resistance, corrosion resistance, and elasticity.

-

High-carbon spring steels are economical and offer excellent strength after heat treatment.

-

Stainless steels are vital for corrosive environments where rust could cause premature failure.

-

Copper alloys are used when electrical conductivity and non-magnetic properties are required.

Material thickness strongly affects spring rate and load capacity.

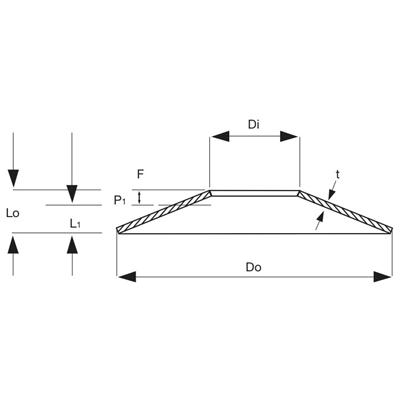

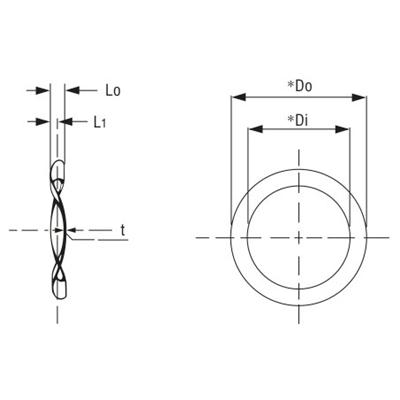

2. Geometry and Deflection Characteristics

The spring rate of a washer is a function of its shape—particularly in Belleville and wave washers. Variables include:

-

Cone angle

-

Washer height

-

Number of waves (for wave washers)

-

Width of cross-section

Finite element analysis (FEA) is frequently used to optimize load-deflection curves and prevent stress concentrations.

3. Heat Treatment

Many spring washers require heat treatment to achieve the correct hardness and ductility. Typical processes include:

-

Austempering for carbon steels

-

Precipitation hardening for alloys like 17-7 PH

-

Solution annealing for stainless steels prior to forming

Proper heat treatment is crucial to avoid cracking, premature fatigue, or loss of spring force.

4. Surface Finishing

Coatings can enhance corrosion resistance or friction properties. Common finishes include:

-

Zinc plating (clear, yellow, or black chromate)

-

Phosphate coating

-

Passivation (for stainless steels)

-

Electroless nickel plating

-

Mechanical plating for hydrogen-sensitive materials

Choosing the right finish extends product life and prevents galling or electrochemical corrosion.

5. Manufacturing Considerations

Stamped washers must be designed with manufacturability in mind:

-

Sufficient clearance between features

-

Proper edge radii to avoid cracking

-

Die-friendly geometry to reduce tool wear

Early collaboration between engineers and the stamping supplier can prevent costly redesigns.

Applications of Stamped Spring Washers

Stamped spring washers appear across nearly every mechanical industry. Examples include:

Automotive

Used in braking systems, drivetrain components, chassis assemblies, and electrical systems to prevent bolt loosening due to vibration.

Aerospace

High-performance alloys and precision-controlled washers are used in turbine engines, landing gear systems, and structural assemblies.

Industrial Machinery

Help maintain preload in high-vibration environments such as pumps, compressors, stamping dies, and motors.

Electronics

Wave and finger washers eliminate play in small assemblies, provide grounding, and maintain tension in connectors.

Energy & Power Systems

Belleville washers are common in bolt tensioning systems on flanges, transformers, and high-pressure pipelines.

Why Stamped Spring Washers Remain a Preferred Solution

Despite the rise of advanced fastening technologies, spring washers remain indispensable due to their simplicity, reliability, and cost-effectiveness. Metal stamping ensures that manufacturers can produce them rapidly and at scale while meeting stringent dimensional and performance requirements.

For engineers, stamped spring washers offer:

-

Reliable, predictable spring behavior

-

Compact size with high load capacity

-

Low per-unit cost

-

Versatile material and coating options

-

Compatibility with automated assembly systems

Their combination of mechanical performance and manufacturing efficiency makes them one of the most enduring components in mechanical design.