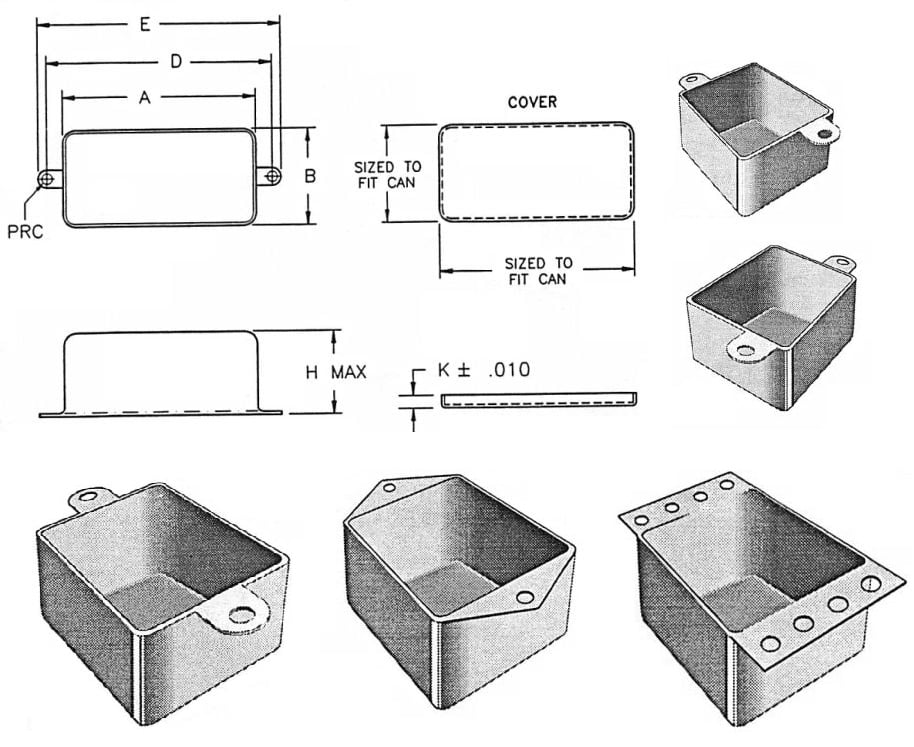

RFI Enclosure Stamping Process

In today’s electronics-driven world, electromagnetic interference (EMI) and radio frequency interference (RFI) are major design concerns across industries—from automotive control modules to medical instruments and telecommunications. Metal enclosures play a critical role in shielding sensitive circuits from unwanted electromagnetic noise. Among the various manufacturing methods available, metal stamping has emerged as one of the most efficient, precise, and scalable processes for producing RFI enclosures.

This article explores the stamping process, material selection, design considerations, and finishing operations involved in manufacturing metal RFI enclosures, with an emphasis on achieving consistent performance and cost efficiency.

Understanding the Purpose of RFI Enclosures

An RFI (Radio Frequency Interference) enclosure is designed to shield electronic components from electromagnetic fields that can cause malfunction, data corruption, or signal degradation. Properly designed enclosures contain electromagnetic energy within a device (preventing emissions) and block external interference from entering (providing immunity).

The shielding effectiveness of an enclosure depends on three primary factors:

-

Conductivity of the material (ability to absorb and reflect EM waves)

-

Continuity of electrical contact across joints and seams

-

Geometry and precision of the formed parts to prevent gaps or resonance points

Metal stamping supports all three by enabling tight tolerances, repeatable contact surfaces, and the use of highly conductive materials like copper, brass, or plated steels.

Why Metal Stamping Is Ideal for RFI Enclosures

Metal stamping is a cold-forming process that uses dies and presses to convert flat sheet metal into finished parts. Compared to machining or casting, stamping provides several advantages for RFI enclosure production:

-

High Volume Efficiency: Progressive dies can form complex enclosures at hundreds of strokes per minute, making it ideal for large production runs.

-

Dimensional Repeatability: CNC-controlled presses and precision dies ensure consistent fit across mating parts—critical for maintaining electrical continuity.

-

Material Utilization: Strip layout optimization and nesting in coil-fed presses minimize waste compared to laser cutting or CNC milling.

-

Integration of Features: Tabs, louvers, ventilation holes, or embossments can be incorporated in the same operation without secondary machining.

Stamped RFI enclosures are widely used in electronics housings, RF filters, power supply covers, and sensor modules.

Material Selection for Shielding Effectiveness

The material chosen for a stamped enclosure determines not only its mechanical strength but also its shielding efficiency. Typical materials include:

-

Copper and Copper Alloys: Excellent electrical conductivity and corrosion resistance; ideal for high-frequency shielding. Common alloys include C11000 (ETP copper) and brass (C26000).

-

Cold-Rolled Steel: Economical and mechanically strong; often plated with zinc, nickel, or tin to improve conductivity and corrosion resistance.

-

Stainless Steel (304 or 316): Used when mechanical strength or environmental durability outweighs the need for maximum conductivity; suitable for outdoor or medical enclosures.

-

Aluminum Alloys (5052 or 6061): Lightweight and corrosion resistant; often used with conductive gaskets to maintain EMI seals.

Sheet thickness typically ranges from 0.3 mm to 1.5 mm (0.012"–0.060"), depending on stiffness, resonance frequency, and enclosure size. The goal is to balance shielding effectiveness with ease of forming.

Stamping Process Overview

The stamping process for RFI enclosures generally follows these stages:

-

Blanking:

Flat sheet metal is cut into blanks or coil-fed strips using a punch and die. The blank geometry defines the initial layout for forming. -

Piercing and Embossing:

Holes, slots, and identification marks are punched. Embossing may be added to strengthen walls or create contact ridges that improve surface continuity between mating parts. -

Forming and Bending:

Using progressive or transfer dies, the flat blank is bent into its final enclosure shape. Precision forming ensures tight corner radii and minimal springback, which are vital for maintaining electrical seals. -

Trimming and Coining:

Edges are trimmed to tolerance, and coining may be applied to flatten contact surfaces or create interlocking seams that improve conductivity. -

Tapping and Assembly Features:

Fastener holes, lances, or snap-fit tabs are added to simplify final assembly and minimize welding or adhesives, which can compromise conductivity.

High-speed progressive dies are often used for small to medium-sized enclosures, while larger housings may use deep-draw or multi-stage forming operations.

Design Considerations for Shielding and Manufacturability

Effective RFI enclosure design must satisfy both electromagnetic and mechanical requirements. Key design points include:

-

Continuous Contact Paths: Avoid discontinuities in bends or joints that break electrical contact. Design overlapping seams or add conductive gaskets where gaps are unavoidable.

-

Bend Radii: Maintain minimum bend radii equal to 1–1.5 times the material thickness to avoid cracking or work hardening, especially in copper and brass.

-

Ventilation and Cable Openings: Any aperture reduces shielding performance. When needed, design openings smaller than one-twentieth of the wavelength of the target frequency to minimize leakage.

-

Tolerance Control: Ensure tight dimensional tolerances at mating interfaces (±0.05 mm typical) to prevent signal leakage through gaps.

-

Tooling Clearance: Account for punch-to-die clearance (typically 5–10% of sheet thickness) to ensure clean edges and extend tool life.

Designers often collaborate closely with stamping engineers early in development to validate die design, ensure formability, and minimize later tooling modifications.

Finishing and Surface Treatments

Surface finishing is a critical step for both corrosion resistance and electrical performance. Common finishes for stamped RFI enclosures include:

-

Tin Plating: Provides good solderability and low contact resistance; commonly used on steel or brass enclosures.

-

Nickel Plating: Offers excellent hardness, wear resistance, and moderate conductivity; suitable for high-wear applications.

-

Zinc with Chromate: Economical corrosion protection for mild steel components.

-

Conductive Paints or Coatings: Sometimes applied to aluminum or nonconductive housings to enhance EMI shielding.

After finishing, parts may be spot welded, clinched, or assembled using conductive fasteners. For modular enclosures, spot welding is often replaced with interlocking tabs to avoid heat distortion.

Quality and Performance Testing

To ensure consistent shielding performance, manufacturers often perform the following tests:

-

Continuity and Ground Resistance Testing: Confirms low-resistance electrical paths across joints.

-

Shielding Effectiveness Measurement: Evaluates attenuation (in dB) across frequency ranges per MIL-STD-285 or IEEE-STD-299.

-

Dimensional and Surface Inspection: Ensures parts meet tolerance and plating specifications.

-

Salt Spray and Environmental Tests: Validate corrosion resistance for outdoor or industrial use.

Process capability (Cp/Cpk) and quality audits such as CQI-9 (heat treat) or CQI-11 (plating) are often applied to ensure repeatability in automotive and aerospace production.

Conclusion

Stamped metal RFI enclosures combine precision, scalability, and superior electromagnetic shielding in a cost-effective package. By integrating smart material selection, precision tooling, and robust finishing processes, manufacturers can achieve enclosures that protect sensitive electronics from the growing challenge of radio frequency interference. As electronic devices continue to proliferate across every sector, the importance of reliable, stamped metal shielding solutions will only continue to grow.