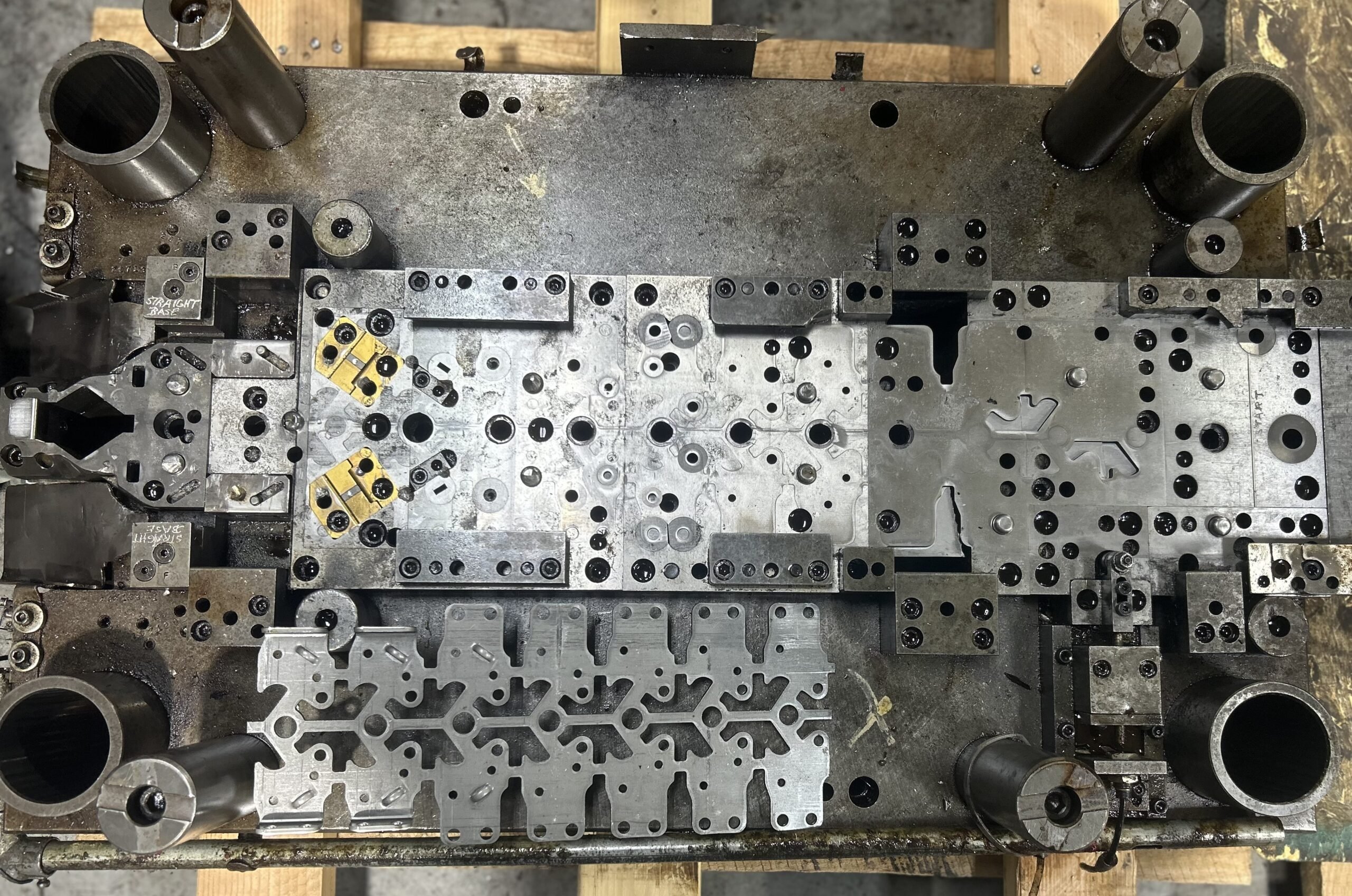

More Dies Sent To Acro

When a Customer Sends "The Rest" of the Dies: What That Really Means

In metal stamping, trust isn’t built with promises.

It’s built with parts.

Recently, we had a customer send us the last of their remaining dies after we successfully took over production on their initial tool transfer. That moment says more than any sales pitch ever could — and it highlights what really matters when transferring customer-owned tooling.

This wasn’t just a logistics decision. It was a performance decision.

Here’s what made it happen — and what it means for manufacturers considering a die transfer to Acro Metal Stamping.

First Transfers Are a Test — Whether Anyone Says It or Not

When a company moves tooling to a new stamper, they rarely send everything at once. And that’s smart.

The first batch of tools is a proving ground. Customers are watching:

- Can the new stamper get the tools running efficiently?

- Do they understand how the parts function — not just how they’re shaped?

- Will quality hold up? Improve?

- Are deliveries consistent?

- How are problems handled?

In this case, the customer started by transferring a portion of their tooling — a mix of parts with real production demands. These weren’t “easy” parts. They had tolerances to hit, schedules to meet, and downstream processes depending on them.

That’s where performance speaks.

What We Focus on During Every Tool Takeover

A successful die transfer is never just “put it in the press and hit go.” At Acro Metal Stamping, we treat every incoming die like it’s already in production — because to the customer, it is.

1. We Learn the Part, Not Just the Tool

Before we even start running, we review:

- Part function and critical features

- Past quality concerns

- Fit or assembly requirements

- Material specs and thickness variation

- Secondary operations

That context matters. A dimension on paper might have ±.005 tolerance — but if it affects a press-fit or electrical contact, we treat it like a critical feature, not just a number.

2. We Stabilize the Process — Fast

Customers moving tooling usually aren’t doing it for fun. Something drove the decision:

- Supplier instability

- Quality drift

- Capacity issues

- Communication breakdowns

- Or the previous stamper closing

Our first priority is process stability:

- Dialing in die and press setup

- Verifying strip progression and feed consistency

- Checking lubrication and material behavior

- Monitoring burr, flatness, and feature formation

- Documenting press parameters

We don’t chase speed first. We chase repeatability. Speed comes after the process is under control.

3. We Treat Customer Tooling Like an Asset — Because It Is

When customers own their tooling, they’re trusting us with a major capital asset.

We:

- Inspect tooling condition upon arrival

- Identify wear, damage, or maintenance needs

- Recommend repairs that protect tool life, not just today’s run

- Store and handle dies properly between runs

- Track performance over time

That proactive approach often extends tool life and improves part consistency — something customers feel quickly.

4. Communication Doesn’t Drop After the First Run

One of the biggest differences customers notice is what happens after parts ship.

We stay engaged:

- Sharing first-run feedback

- Discussing improvement opportunities

- Flagging tooling risks early

- Coordinating schedules clearly

Customers don’t feel like their tooling disappeared into a black box. They feel like they gained a partner.

The Moment That Says Everything

After the initial tools had been running successfully — hitting quality targets, shipping on time, and running predictably — the customer made a decision.

From their perspective:

- Quality was consistent

- Issues were addressed quickly

- Production felt stable

- Their tooling was being cared for

- Communication was clear

Moving the remaining dies simplified their supply chain and removed uncertainty. That’s the real win.

They sent the rest of their dies.

Not because of a discount.

Not because of a contract trick.

Because performance reduced risk.

Why This Matters to Other Manufacturers

If your company owns tooling and is considering a transfer, this is the pattern you want:

- Start with a few tools

- Evaluate real production performance

- Expand based on results

That’s exactly how long-term stamping partnerships are built.

The biggest fear in a tooling move is disruption. The right stamper reduces that fear by:

- Respecting your tooling

- Understanding your parts

- Running stable processes

- Communicating clearly

- Delivering consistently

When those things happen, sending the “rest of the dies” stops feeling risky — and starts feeling like the obvious move.

At Acro Metal Stamping, Takeovers Are a Core Strength

We specialize in:

- Customer-owned tooling

- Tool transfers from closing or overloaded suppliers

- Stabilizing legacy tooling

- Getting existing dies back to reliable production

We know we’re being evaluated from the first shipment. That’s why our focus is simple:

Run good parts. Protect the tools. Communicate clearly. Repeat.

When customers respond by trusting us with all their remaining tooling, that tells us we’re doing our job right.

And for manufacturers facing supplier changes or uncertainty, it shows what a successful transition should look like.

Thinking about transferring tooling?

Start with a few parts. Let the performance speak.