Specialize In Customer Owed Tooling

Acro Metal Stamping: The Ideal Partner for Transferring Your Customer-Owned Tooling

In the world of precision metal stamping, tooling ownership and performance are two of the most critical factors that determine production success. For manufacturers who rely on external stampers, the need to transfer dies—whether due to capacity constraints, quality challenges, or a stamper closing their doors—is a reality that demands a reliable partner. That’s exactly where Acro Metal Stamping shines. With over 80 years of experience, deep technical expertise, and a specialized approach to customer-owned tooling, Acro has built a reputation as a trusted destination for die transfers and long-term stamping partnerships.

A Legacy of Precision and Customer Focus

Founded in 1942 and based in Milwaukee, Wisconsin, Acro Metal Stamping has spent decades mastering the craft of metal stamping across a broad range of industries—automotive, aerospace, electronics, industrial equipment, and more. Its longevity reflects more than just survival; it represents a commitment to evolving stamping technology while maintaining a strong customer focus. The company’s ISO 9001-2015 certification underscores its dedication to quality, process control, and continuous improvement.

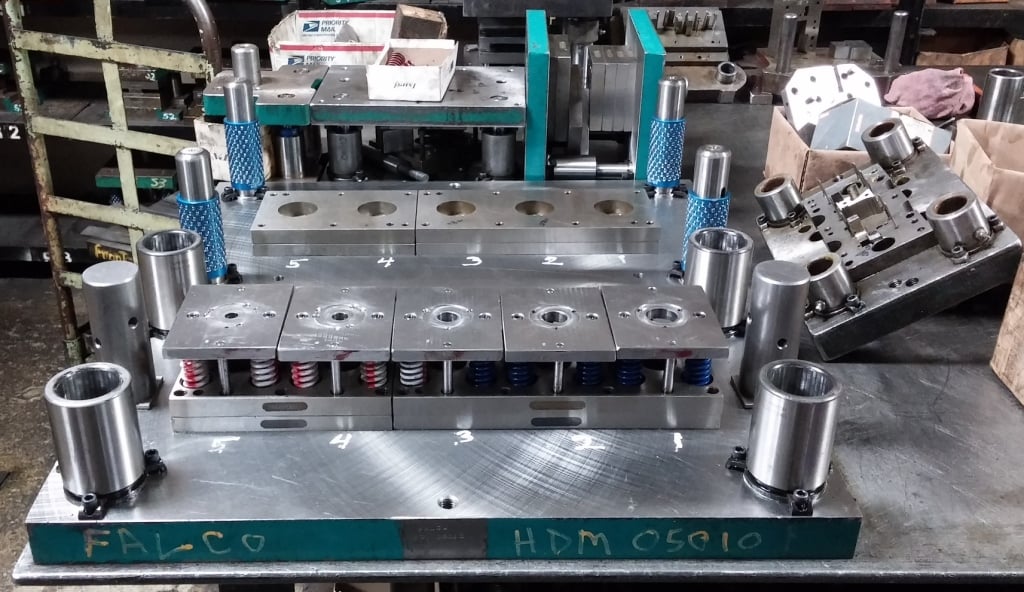

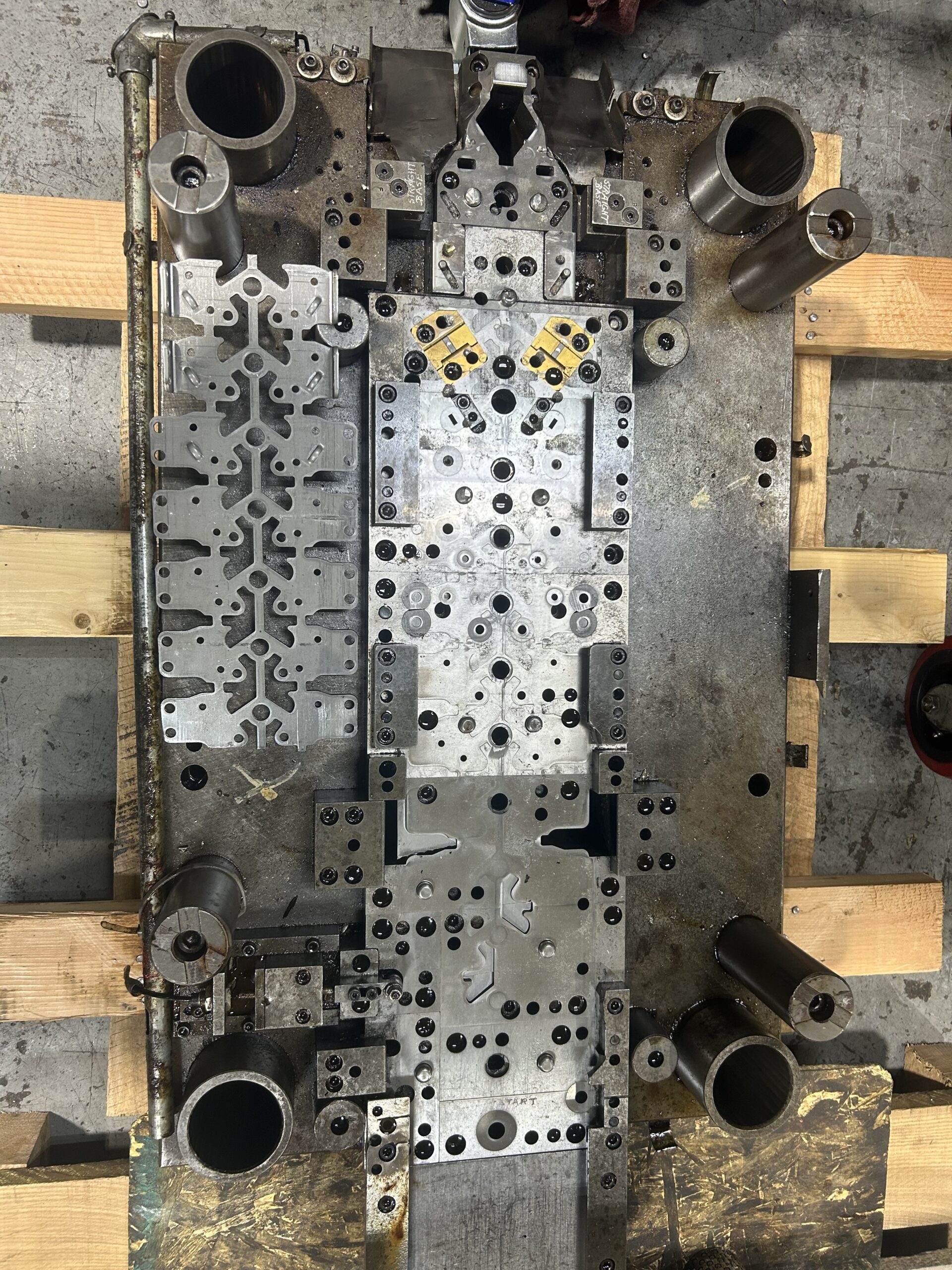

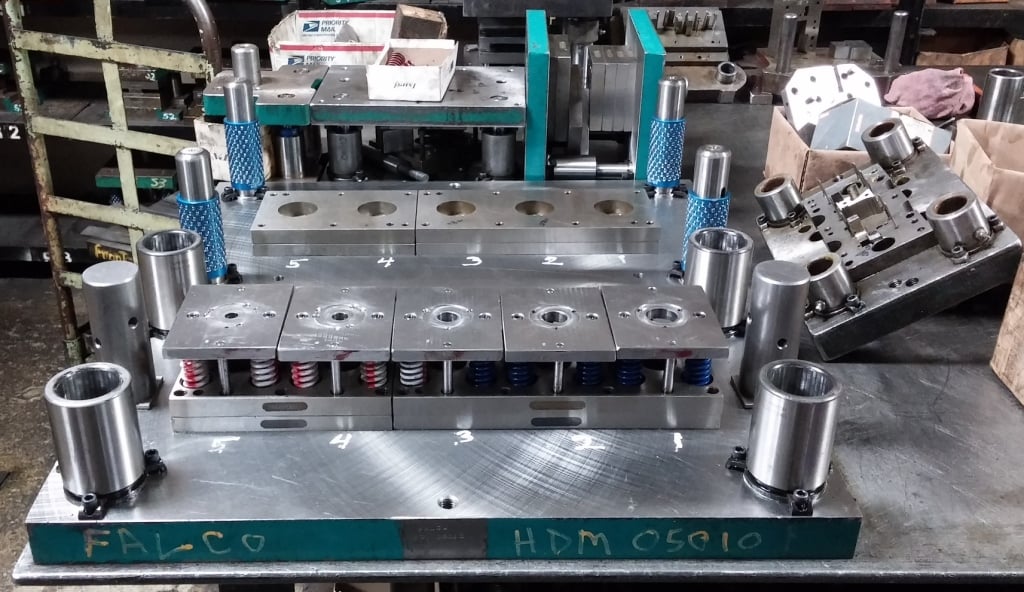

At the heart of Acro’s capabilities is not only its ability to produce precise, high-quality stampings but also its comprehensive in-house toolroom that designs, builds, maintains, and retrofits dies. This in-house vertical integration gives Acro a unique edge: unlike many contract stampers that either outsource tooling work or avoid complex die transfers, Acro embraces tooling as a cornerstone of their service offering.

Specializing in Customer-Owned Tooling Transfers

One of the standout services that sets Acro apart in today’s stamping landscape is its die transfer and takeover process. Many stampers shy away from taking on dies that were built elsewhere—especially if they are older, worn, or designed for different presses—preferring instead to build new tools or stick strictly to their own tooling systems. Acro, however, takes a fundamentally different approach: they actively help customers transition existing dies into their facility, restoring performance and integrating them into production.

This capability is invaluable when a current stamper is closing or unable to support your tooling needs. The die transfer process at Acro is designed to be transparent, collaborative, and engineered for success:

-

Free tooling evaluation: Acro begins by assessing your tooling to determine compatibility with its presses and identifying any retrofitting work needed.

-

Initial setup and trials: Once tooling is received, Acro adjusts the dies to fit their servo presses, conducts initial runs, and inspects parts closely with your team to ensure specs are met.

-

Full production & documentation: After validation—including full PPAP documentation when required—Acro transitions your tooling into scalable production with consistent quality and on-time delivery.

Unlike some shops that might view transferred dies as a burden, Acro’s team sees them as opportunities to demonstrate their tooling expertise. Their fully equipped toolroom—staffed with experienced designers, machinists, and die makers—enables them to repair, retrofit, and enhance dies in ways that reduce maintenance issues and extend tooling life.

How Acro’s Tooling Expertise Benefits Manufacturers

If you are facing a die transfer, choosing a partner like Acro offers several concrete advantages:

1. Seamless Integration With Advanced Press Technology

Acro’s facility houses 20+ servo and mechanical presses with capacities up to 200 tons, giving them flexibility to accommodate a wide range of die sizes and production requirements. This includes the ability to run dies more efficiently and with less shock to tooling compared to older mechanical presses—resulting in lower maintenance costs and improved part quality.

2. Enhanced Tooling Performance and Longevity

Many transferred dies come in with wear, misalignment, or outdated features that limit quality or consistency. Acro’s engineers can re-engineer dies for optimal performance, updating components, correcting issues, and even improving manufacturability. These enhancements not only make dies production ready but often improve part quality and cycle life.

3. Reduced Lead Times and Production Risk

Having tooling troubles at a key supplier can be a bottleneck. When Acro takes over tooling, they focus on rapid setup, validation, and documentation, minimizing disruption. This proactive process improves delivery performance and helps keep your supply chain stable—even when a previous source fails you.

4. Collaborative Quality Assurance

Quality control isn’t an afterthought at Acro. The company’s processes include detailed part inspection, SPC, and PPAP support, ensuring that parts stamped from transferred dies meet your specifications every run. This collaborative stance—working with your quality team during validation—builds trust and ensures alignment with your expectations.

Proven Success with Tool Transfer and Long-Term Partnership

Acro’s commitment to die transfers isn’t just theoretical—real customer success stories highlight the impact of their approach. One case involved a customer moving 80+ dies from a struggling stamper to Acro. The result was not only restored production stability but measurable improvements in lead times, part quality, and tooling maintenance efficiency. Three years after the transfer, that customer has continued to rely on Acro, recognizing a 20% improvement in delivery performance and strengthened production reliability.

That kind of outcome underscores why Acro is more than a service provider: they are a strategic partner for companies needing to safeguard their stamping programs and protect investments in customer-owned tooling.

Conclusion

For manufacturers navigating a stamper closure, quality challenges, or tooling performance issues, the decision about where to transfer your dies cannot be taken lightly. It requires a partner with deep tooling expertise, flexible press capabilities, and a collaborative approach to quality and production. Acro Metal Stamping delivers on all these fronts—specializing in customer-owned tooling transfers while providing a full suite of metal stamping services backed by decades of experience. Whether you need to relocate dies, retrofit tooling, or improve part quality, Acro is uniquely positioned to make the transition smooth, efficient, and ultimately successful.