Explaining The Break Edge

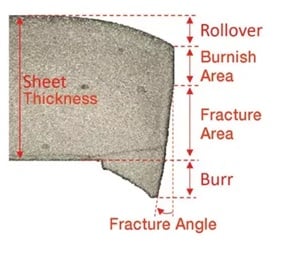

During the stamping process metal is not so much cut as it is broken out. This means that a clean edge only exists for a portion of that edge; and a rougher broken edge shows for the rest. With traditional punch presses, a good standard was about 1/3 of the material thickness would be cut sheer and the other 2/3 would be broken.

The "sheer" or "land" portion of the cut can be improved upon via several methods. Multiple passes can be done to shave down the edge. Lowering the clearance distance between cutting edges can also increase the cut length (but the closer the clearance the more die maintenance required). However, our high tech sevro presses do allow us to cut that clearance down and not increase piece price on a 50% Min Sheer Edge